With skilled waterproofers and tradies in house, Danrae Group can quickly – and seamlessly – solve any waterproofing issues. That’s no reason to avoid taking immediate action, however.

A smooth process doesn’t always mean it’s a basic process, and the longer you put off a fix, the larger the problem is likely to be. When we discovered concrete spalling in a Rose Bay apartment block, we performed a full diagnostic, created a solution design and implemented a permanent waterproofing plan.

We thought we’d take you through one element of the repair process for the Rose Bay project to illustrate why comprehensive waterproofing solutions are essential to maintain and protect your strata property or luxury home… and why delaying treatment – or taking shortcuts – should never be an option.

The Rose Bay project

The owner of the Rose Bay apartment block contacted Danrae Group after discovering a damaged ceiling. Our first step is to perform a full diagnostic, and what we found was extensive concrete spalling and potentially concrete cancer.

Concrete spalling and concrete cancer are consecutive stages of the same issue, and they occur when water or air seeps into concrete and affects the reinforcing steel that supports concrete structures. It causes the steel to rust and expand, cracking the surrounding concrete and letting even more water and air in – which accelerates the damage.

The treatment process may involve removing the affected concrete, identifying the extent of damaged steel, cleaning or replacing the steel, building up the missing concrete area with primers and other materials, adding a protective coating – and then laying a waterproofing membrane. For this project we used Sika products.

Preparation - Apply Sika Top-110 EpoCem Bonding Primer & Reinforcement Corrosion Protection (6m x 6m)

- Removed all weak, damaged and deteriorated concrete.

- Removed rust, scale, concrete, dust and other loose material over the steel reinforcement bar with abrasive blast cleaning techniques and high-pressure water-blasting to SA 2 in accordance with ISO 85010-1.

- Cleaned exposed concrete surface by removing dust and loose material.

d) Pre-wet concrete surface prior to application of the bonding primer – thorough drying required before application. - Applied bonding primer using SikaTop-110 EpoCem with hard brush or spray gun. To achieve a good bond, SikaTop-110 EpoCem must be applied well into the substrate, filling all pores (minimum layer thickness 0.5 mm).

- Treated exposed steel with two coats of reinforcement corrosion protection coating. Allowed two to three hours between coats.

- Applied repair mortar.

Concrete Repair - Apply Sika MonoTop-612N High Strength Concrete Repair Mortar (6m x 6m)

- Applied structural repair mortar using Sika MonoTop-612 N. Pressed well into substrate using trowel while bonding primer still tacky.

- Built up layers, with each layer required to stiffen before applying subsequent layers. Where layers cannot be applied ‘wet on wet’ or if more than 24 hours elapses between layers, we also apply a bonding primer of SikaTop-110 EpoCem.

- Once mortar had stiffened, finished with hand and spray application.

- Applied layers to minimum of 30mm above steel reinforcement.

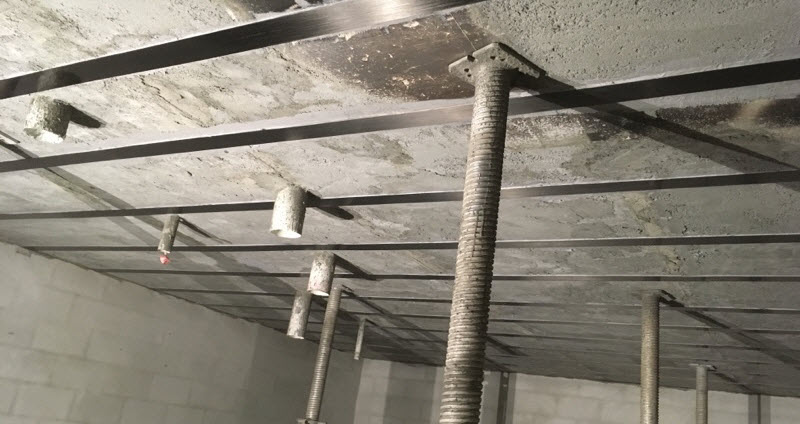

- Subsequent to installation of the repair mortar, left acrow props in place until installation of the carbon strips in next stage.

Curing and finish - Apply Resin Adhesive Sikadur-30 and Structural Strengthening Sika CarboDur-S812 (83 Lineal Metres)

- Provided 28 days’ curing time for repair mortar Sika MonoTop-612 N to reach compressive strength of 70 N/mm2 (70 mPa).

- Applied Sikadur-30 resin adhesive.

- Installed Sika Carbondur S812, maximum 500mm centre to centre with fibre direction parallel to existing steel bar reinforcements.

- Organised for apartment directly above the damaged concrete to be vacant for 24 hours to ensure proper curing.

- Applied Sikadur-30 and Sika Carbondur Plate S812.

The process above focused on concrete repair and is just one stage of our diagnostic, design, remediation, waterproofing and preventative maintenance solutions. In between, we also look after everything from street closures to stakeholder communication.

Best option waterproofing

When people find a large leak, they generally seek immediate help. Unfortunately, other signs of a problem don’t always trigger action. Bubbling paint, rust stains and ceiling cracks may indicate concrete spalling. If left untreated it will develop into concrete cancer which can involve a much larger – and costlier – fix.

According to Ron Caruana, Founder and Project Manager with Danrae Group, knowing Danrae Group can fix any issue doesn’t mean you should leave it. “People do tend to ignore the warning signs. It’s common for many people to contact us only after it’s become a much bigger issue.”

Danrae Group has leading waterproofing expertise and provides full project management, so we can treat anything from a leaking planter box to major concrete cancer.

If you are seeing signs that might indicate a problem, don’t leave it too late. Contact us for fast-response and permanent waterproofing solutions. Read more about our waterproofing experts.

1800 326 723

1800 326 723